Significantly increase process capability in injection molding

Fully customized process optimization for any combination of machine, material and process

Mastering the triad of machine, material and process

A manufacturer of injection molding machines wants to enable its customers to increase process capability. Growing amounts of recycled material add further complexity. Material properties can differ even within a batch, impacting i.e. material flow. The consequences are over- and under-molding or non-compliance with specifications for finished products. The aim is to offer a solution that optimizes the many different combinations of machines, material and processes.

No data available

The data for an AI solution is not accessible!The high variance of machine designs in combination with different materials and processes is a challenge. As a result, it is hardly possible for a single company to collect sufficient data for comparable combinations on its own. In a laboratory setting, the variance from the field can hardly be mapped. Collecting data directly from the user often fails due to the fundamental problem of using AI in industrial settings. Industrial users want to protect their process knowledge to ensure their competitiveness. But without this data, it is not possible to train a machine learning model to optimize process stability.

Solution

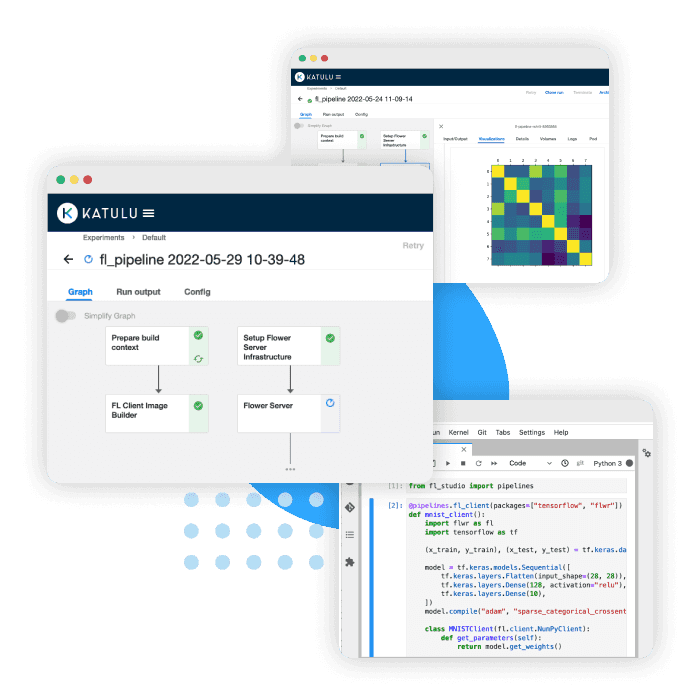

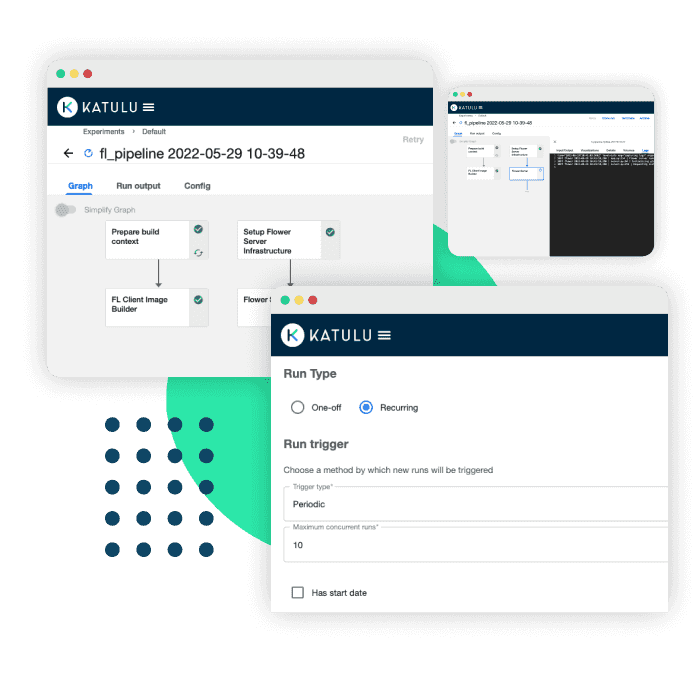

Train AI models locally without sharing source dataKatulu's unique decentralized approach to machine learning enables the use of AI across enterprise boundaries, while all sensitive data remains securely with industrial users. This enables training of AI models directly at the user's site. This results in robust optimizations taking into account material variants, different machine layouts and processes. For each combination, a user-specific but anonymized AI model is calculated on the edge device directly at the machine. This is based on many different models and thus adapts perfectly to the respective set up. The Edge Device also enables intelligent and automatic control of the injection molding process in real time to compensate for material fluctuations and reduce scrap.

Does this scenario sound familiar?

Let us talk about your use case. We look forward to hearing from you.

Book AppointmentThe initial AI model

The development of a decentralized model begins with data acquisition. First, initial data sets from the injection molding machines are collected in the technical center or laboratory in order to train an initial model. Here, Katulu initially concentrates on the data that can be tapped directly at the control system. A decisive factor in data acquisition is the labeling of the data, i.e. the labeling of the data sets according to defect cases and quality grades. For this purpose, experiments are carried out with different machine parameters and cycle times, and the test results are evaluated to correlate features such as surface gloss, burr formation or warpage with the control data. Historical data that can be assigned to a specific failure case is also a valuable source of data.

With this data, an initial AI model is trained with the key factors influencing the process, with the aim of enabling predictions of quality in the running process.

MVP or The first functional product

The first model is rolled out along with the application to help the user optimize their process. Here, it is critical to capture the user's feedback on their production results in order to mark up the data. For this purpose, Katulu usually uses a separate tablet to avoid interfering with the injection molding machine. This initial version of the minimum viable product, including the required edge hardware, is made available to pilot customers. The data collected with the application is used together with the data from the respective controller to train more robust and versatile models using federated learning for a range of users, molds, materials and processes.

Refinement with Clustered Federated Learning

The model is trained on all connected injection molding machines using federated learning. Katulu's federated clustering algorithm enables the machine manufacturer to automatically group comparable combinations of machine, material and process across company boundaries. The resulting models are optimally matched to the various machine types, peripherals, configurations, materials, process data, etc. of each user. This guarantees the best possible optimization and automatic control of the injection molding process. Of course, without sensitive information leaving the respective production.

Continuous improvement

Continuous training and deployment cycles continuously improve the model. Special model metrics (federated analytics) also ensure that these improvements also represent an improvement in the model for the respective user. When this maturity level is reached, it is the right time to train more advanced models that contribute to the improvement of the overall process stability.

Self-optimizing machine

Only when a model has been extensively tested in the field and its high robustness and accuracy has been proven through numerous iterations and validations, will it be possible to intervene in the injection molding process in a controlling manner, for example to compensate for material fluctuations and reduce the amount of waste. The edge device directly at the machine enables inferences based on live data in hard real time to use the result for fine-tuning the process.

Are you ready for your journey into distributed machine learning?

We look forward to supporting you with your ideas and projects.

Book AppointmentAdvantages of the Katulu Platform

The challenges in plastics engineering are becoming more complex, such as the increasing complexity of variants with increasing recycled content. The benefits of using Federated Learning for the plastics industry are numerous and represent a critical step in addressing these new challenges.

Increasing productivity & reduced batch sizes

AI-supported manufacturing processes are the prerequisite for higher productivity with reduced batch sizes. Katulus technology creates this prerequisite at the technical and organizational level for simple and straightforward implementation.

Higher machine availability

Do you have world-class extruders, injection molding machines, or other plastics or rubber processing machinery that rarely breaks down? Katulu helps you capture the infrequent failures of system-critical components to prevent machine breakdowns early on in terms of predictive maintenance and sustainably extend the product lifecycle.

Increase process stability

Create the conditions for increased process stability for all machines and material pairings in the field with Katulu and increase quality with reduced scrap.

Harnessing knowledge

Whether it's employee turnover or demographic change, Katulu makes it easy for you and your users to capture and leverage empirical process knowledge across organizational boundaries. Because your industrial users learn from each other without learning about each other through the use of Katulu Federated Learning, your users are still protected.

Automatic clustering as an enabler of AI

Machines are used in different environments and processes and are designed accordingly. This makes it difficult to determine which set ups can be trained together when no information is shared.

Katulu Federated Learning identifies which machines and assemblies can be trained together according to their design and automatically groups them into clusters that can be trained together. Changes to the design of a machine are automatically detected and result in an adjustment to the grouping. This ensures that each machine - no matter how individual - learns from other comparable machines or assemblies.

True data sovereignty

Protect everyone's data sovereignty. Machine builders, plant operators and industrial users benefit from gaining knowledge without sharing sensitive data.

Are you ready to use AI the right way?

Book a free consultation with our experts to talk about unlocking your AI potential.

Book meeting